MS SQUARE AND RECTANGULAR PIPES

MS Square and Rectangular Pipes (Mild Steel Hollow Sections) are widely used in structural, engineering, and fabrication applications due to their high strength, versatility, and durability. These pipes are manufactured using Electric Resistance Welding (ERW) technology, ensuring seamless precision and enhanced performance. MS Hollow Sections offer excellent load-bearing capacity, making them ideal for construction, industrial frameworks, and mechanical applications.

KEY FEATURES

Superior Weldability & Fabrication Flexibility – Can be easily cut, welded, and shaped as required.

Corrosion Resistance with Protective Coating – Available with optional surface treatments for increased longevity.

Versatile Applications – Suitable for building structures, machinery frames, fencing, and industrial fabrication.

Available in Various Sizes & Thicknesses – Customizable dimensions to meet diverse industry needs.

Manufactured to Industry Standards – Produced as per IS 4923, ASTM, and other global standards.

Raw Material Used – 100% Pure Steel (No Scrap steel is used)

Applications

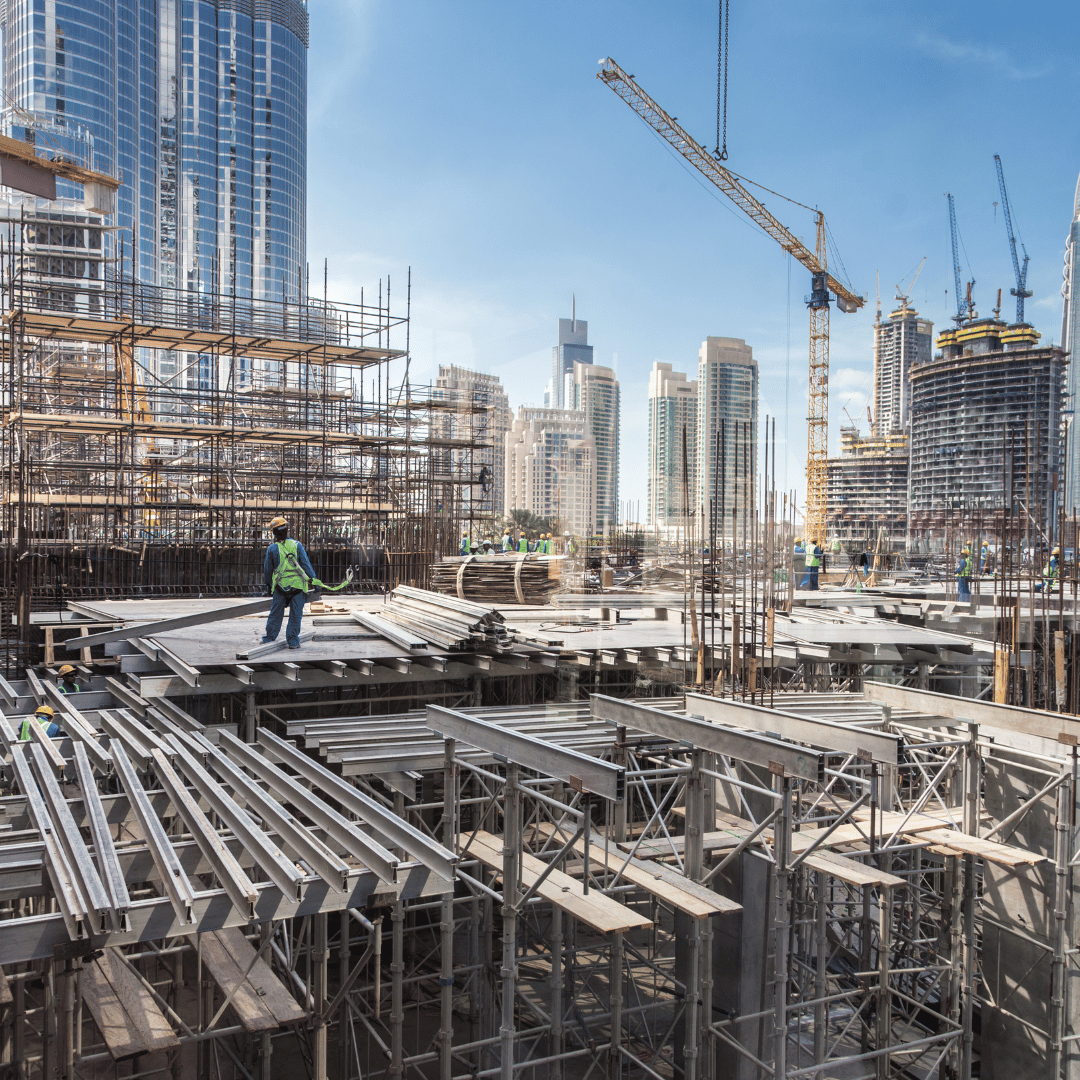

Construction & Infrastructure

Used in bridges, buildings, and structural frameworks where high strength and durability are essential. Widely preferred for their load-bearing capacity and ease of fabrication.

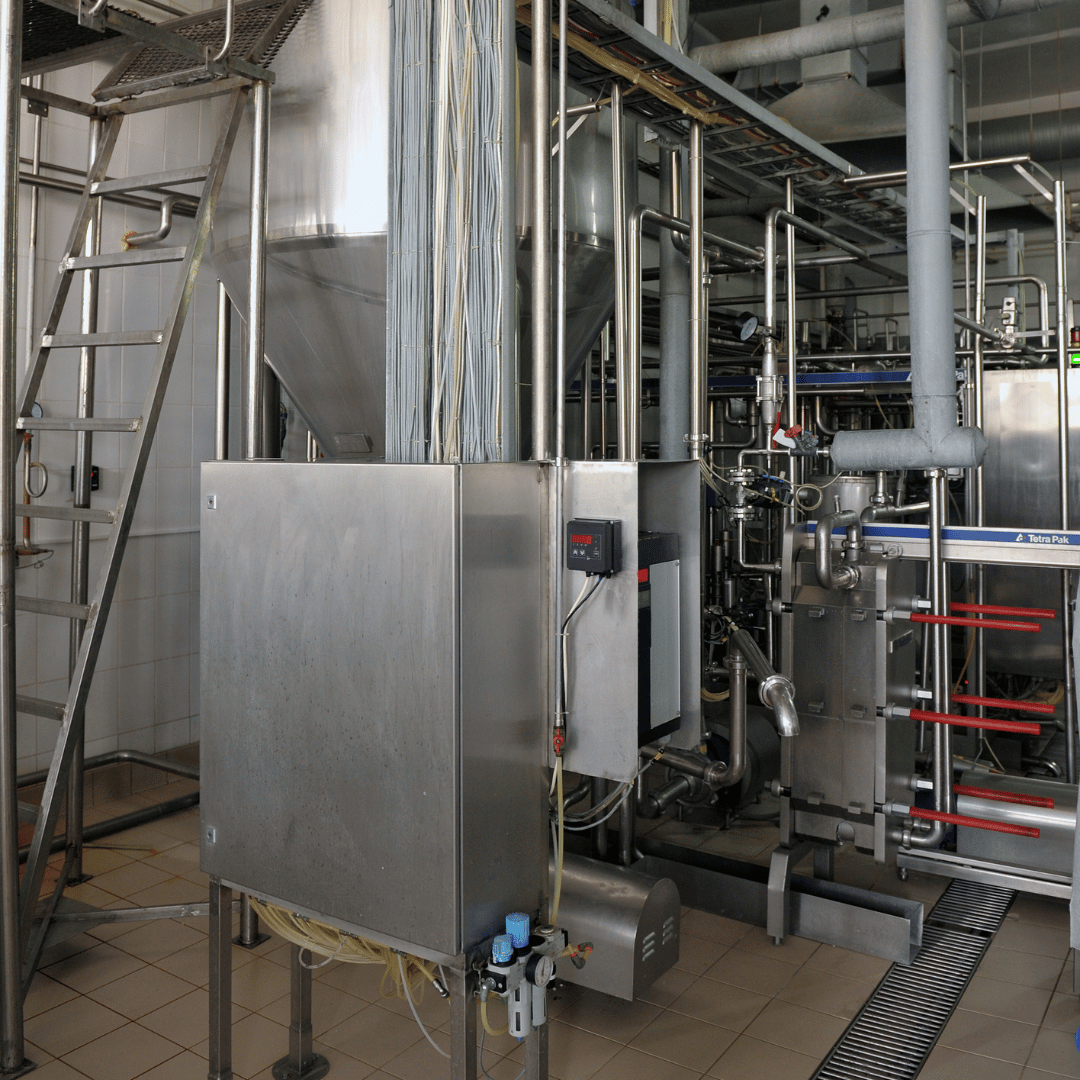

Industrial Machinery & Equipment

Provides structural support in machines, conveyor systems, and heavy equipment setups. Ensures dimensional accuracy and long-lasting performance in industrial use.

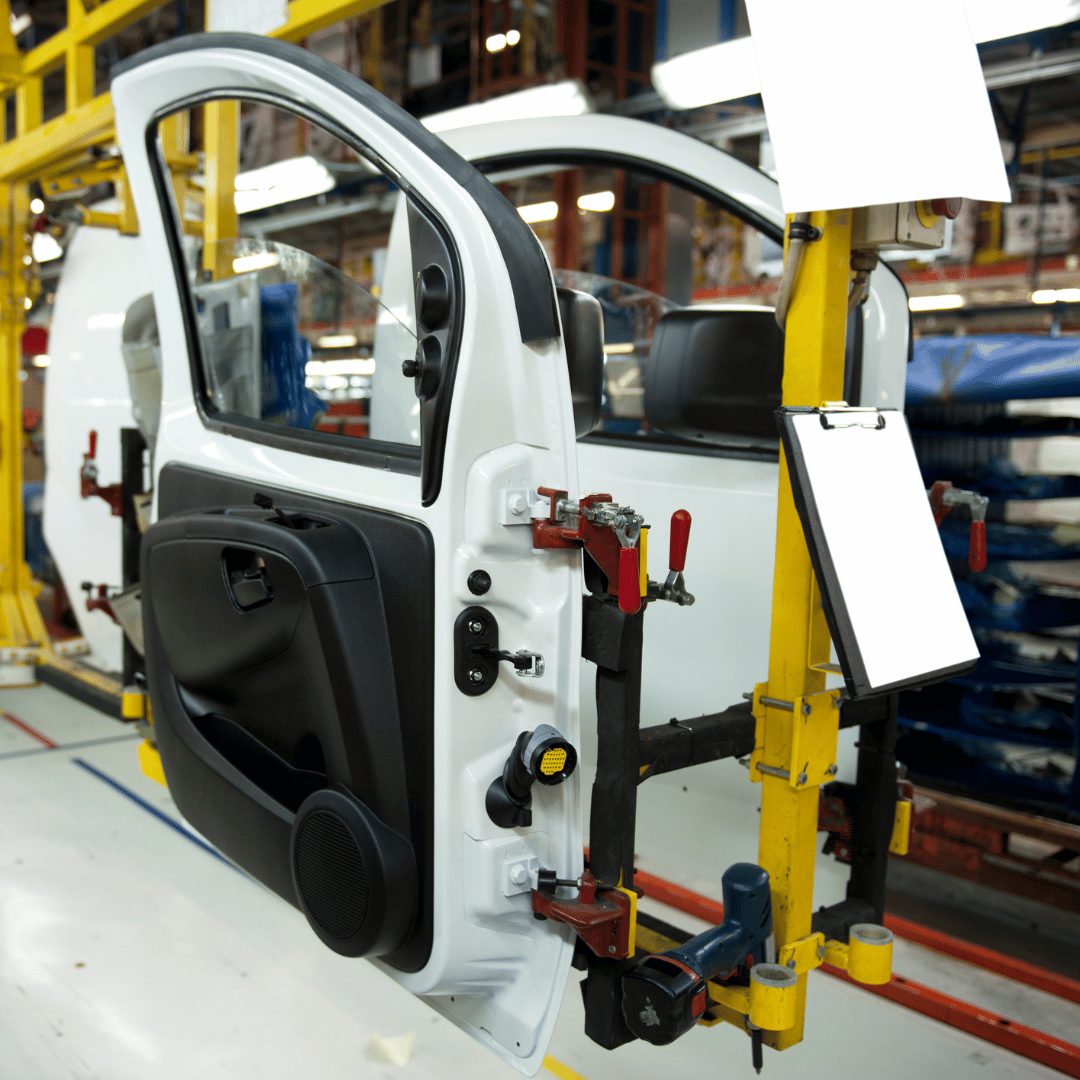

Automobile & Transportation Industry

Used in chassis, trailers, and vehicle body structures for strength without excess weight. Ideal for enhancing safety, durability, and fuel efficiency in transport design.

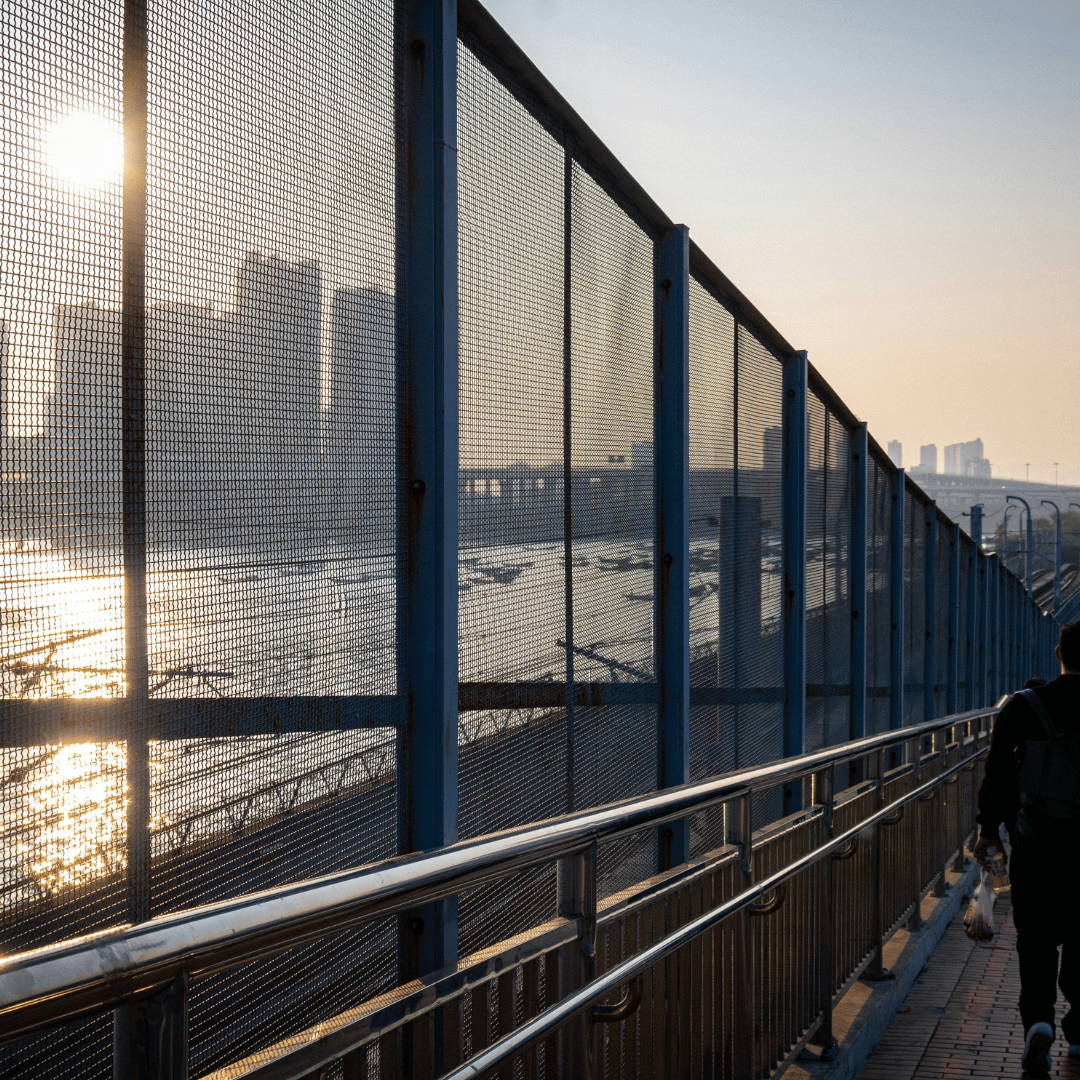

Fencing & Railings

Commonly applied in boundary fences, protective barriers, and security enclosures. Offers a strong, weather-resistant solution with clean and modern aesthetics.

Pre-Engineered Buildings (PEB)

Plays a key role in warehouses, industrial sheds, and modular steel structures. Preferred for fast installation, structural strength, and long-term reliability.

Furniture & Interior Design

Ideal for frames, shelves, partitions, and sleek modern furniture styles. Combines visual appeal with strength, making it perfect for functional interiors.

IS Standards & Specification

| SQUARE & RECTANGULAR PIPES | |

| IS: 4923 (Edition 1997) | |

Why Choose Asian Steels?

-

Industry Leadership

Asian Steel is a pioneer and leading manufacturer of MS Square and Rectangular Pipes in India, with a proven track record of delivering high-quality products and exceptional customer service.

-

Premium-Grade MS Pipes

Asian Steels provides high-strength MS Square & Rectangular Pipes that deliver excellent structural integrity and durability.

-

Precision Engineering & Quality Assurance

Manufactured using ERW technology, ensuring smooth finishes and dimensional accuracy.

-

Custom Sizing & Thickness Options

Available in multiple sizes and thicknesses to meet the demands of diverse applications.

-

Exceptional Load-Bearing Capacity

Built for high-impact and heavy-load applications, ensuring long-term performance.

-

Superior Weldability & Fabrication Flexibility

Easily cut, bent, and welded, making them suitable for various industrial and structural projects.

-

Reliable & Fast Delivery

We ensure on-time order fulfillment, catering to bulk and custom project needs efficiently.

-

Built From Purity

At Asian Steels, every product is crafted from 100% pure steel – we never use scrap. This ensures superior strength, consistent quality, and long-term reliability in every structure built with us.

Frequently Asked Questions (FAQs)

MS Hollow Sections are widely used in construction, industrial frameworks, PEB structures, fencing, and machinery manufacturing.

Yes, MS Square and Rectangular Pipes have excellent load-bearing strength, making them ideal for bridges, high-rise buildings, and industrial structures.

MS Square and Rectangular Pipes offer several advantages over other structural materials, including higher strength, better durability, greater versatility, easier fabrication, and lower cost.

The selection of the right size and thickness depends on various factors, including the intended application, load-bearing requirements, and environmental conditions. Our technical team can assist you in choosing the optimal specifications for your project.

Standard lengths typically range from 6 meters to 12 meters. However, we can also provide custom lengths to meet your specific needs.