SAW PIPES

Narmada SAW (Submerged Arc Welded) Pipes are high-quality large-diameter welded pipes designed for oil & gas transportation, water pipelines, and structural applications. These pipes are manufactured using the Helical Submerged Arc Welding (HSAW) process, which ensures deep penetration, high weld integrity, and superior strength. HSAW pipes, also known as Spiral Welded Pipes, are widely used for high-pressure and long-distance fluid transmission systems.

KEY FEATURES

Large-Diameter & High-Pressure Tolerance – Designed for long-distance transportation of fluids and structural frameworks.

Corrosion & Weather Resistance – Available with anti-corrosion coatings for enhanced durability in harsh environments.

Cost-Effective & Efficient – Spiral welding allows for greater pipe length and larger diameters at a lower cost compared to longitudinally welded pipes.

Customizable Length & Thickness – Available in various wall thicknesses, coatings, and end finishes.

Manufactured to International Standards – Produced as per national and international specifications.

Raw Material Used: 100% Pure Steel (No Scrap steel is used)

Applications

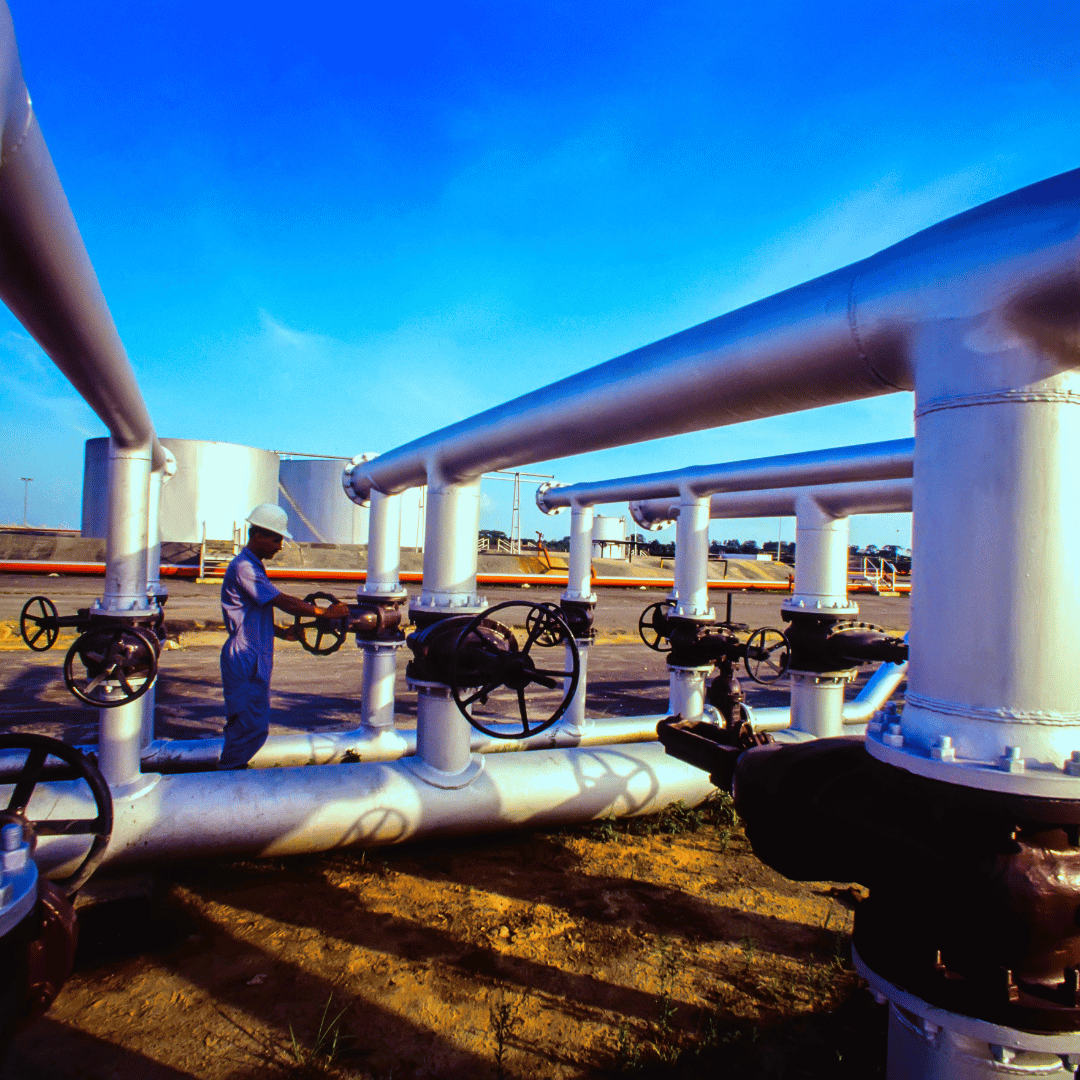

Oil & Gas Pipelines

Used in long-distance transportation of crude oil, natural gas, and refined petroleum. Offers high strength, weldability, and resistance to internal pressure and corrosion.

Water Supply & Sewage Systems

Suitable for municipal and industrial water pipelines, including sewage disposal. Ensures smooth flow, long service life, and compatibility with large-diameter systems.

Structural & Industrial Uses

Ideal for heavy-duty structures like bridges, piling, and industrial frameworks. Known for its load-bearing capacity and suitability in large-scale infrastructure.

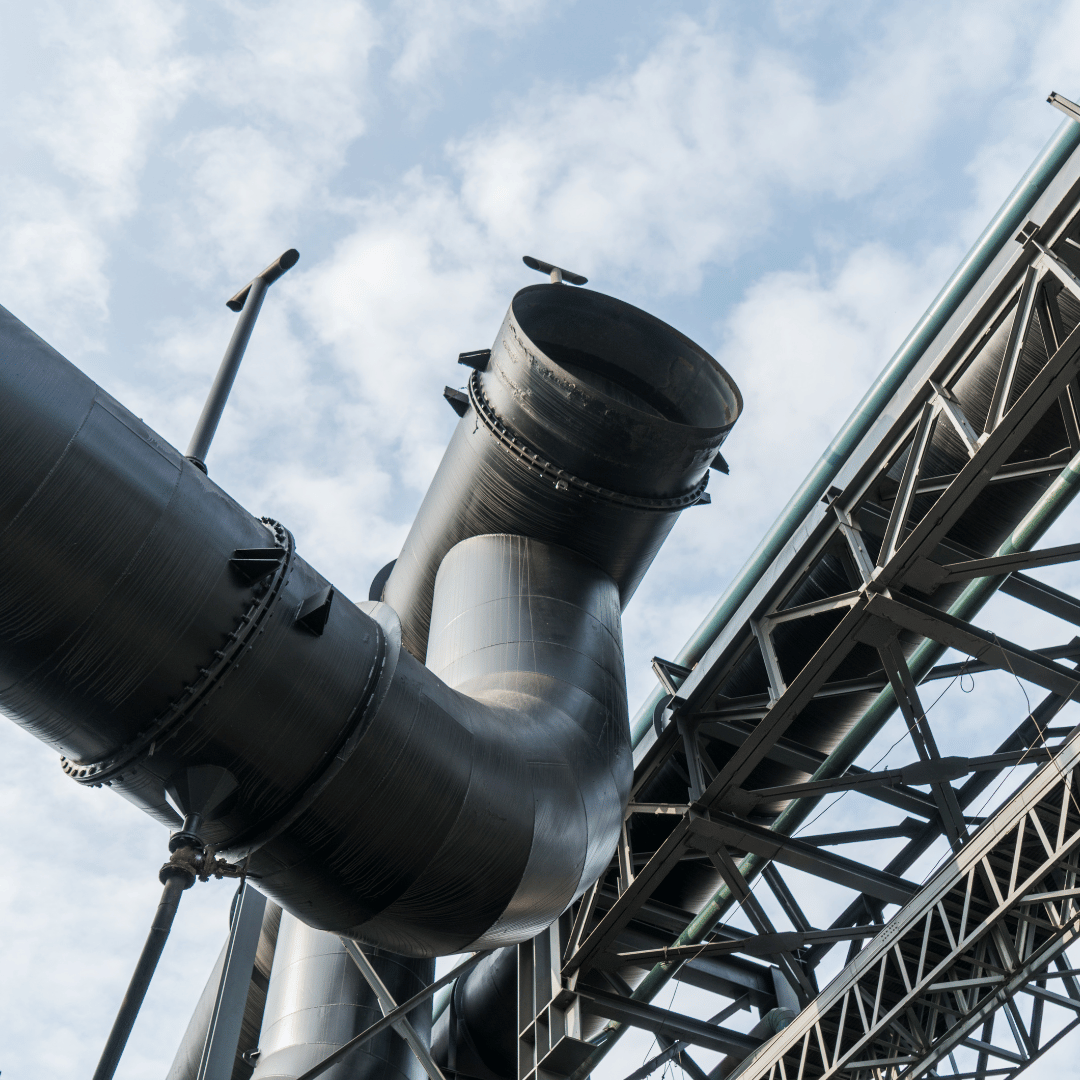

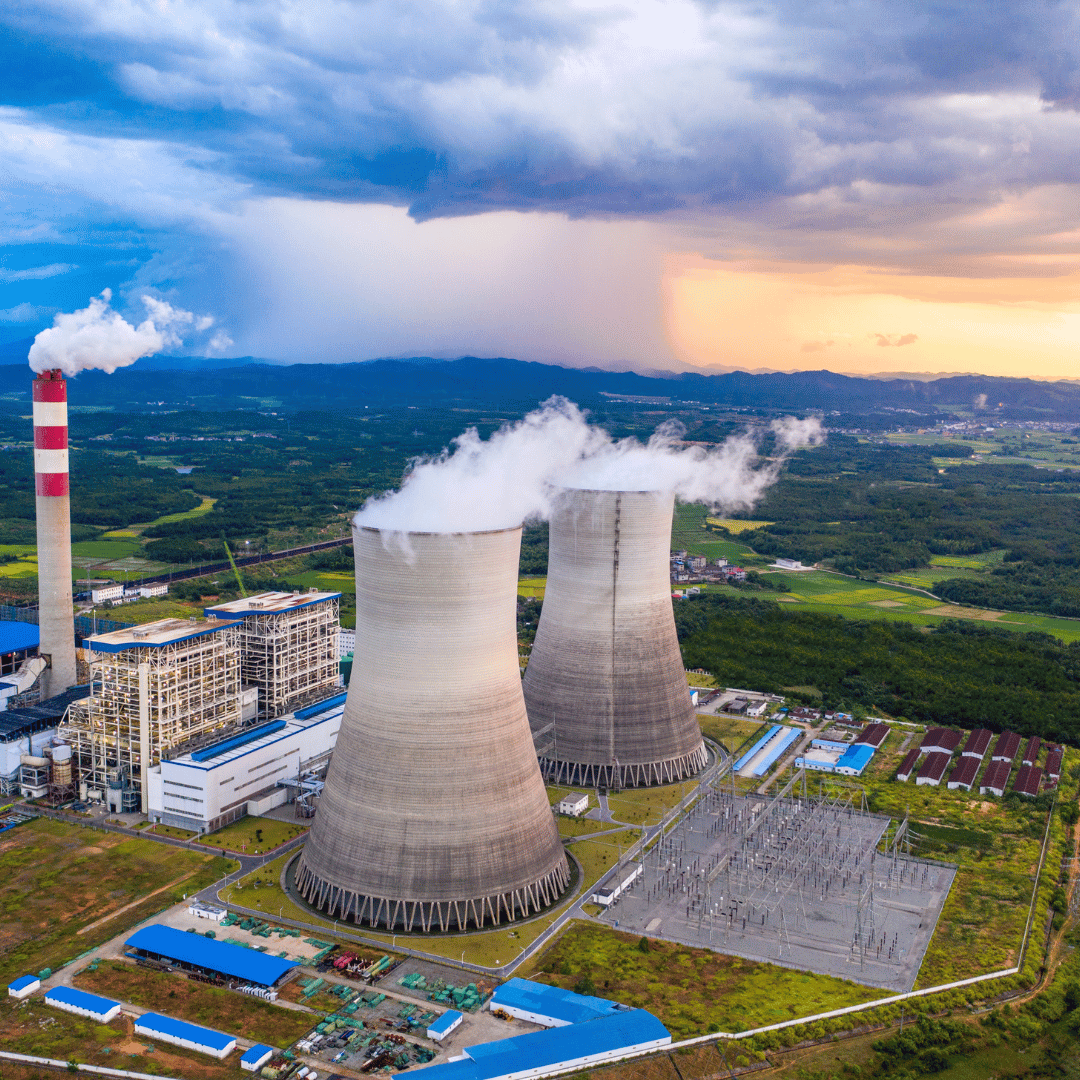

Hydroelectric & Thermal Power Plants

Utilized in high-pressure fluid transport and cooling water circulation systems. Performs efficiently under extreme temperatures and operational stress.

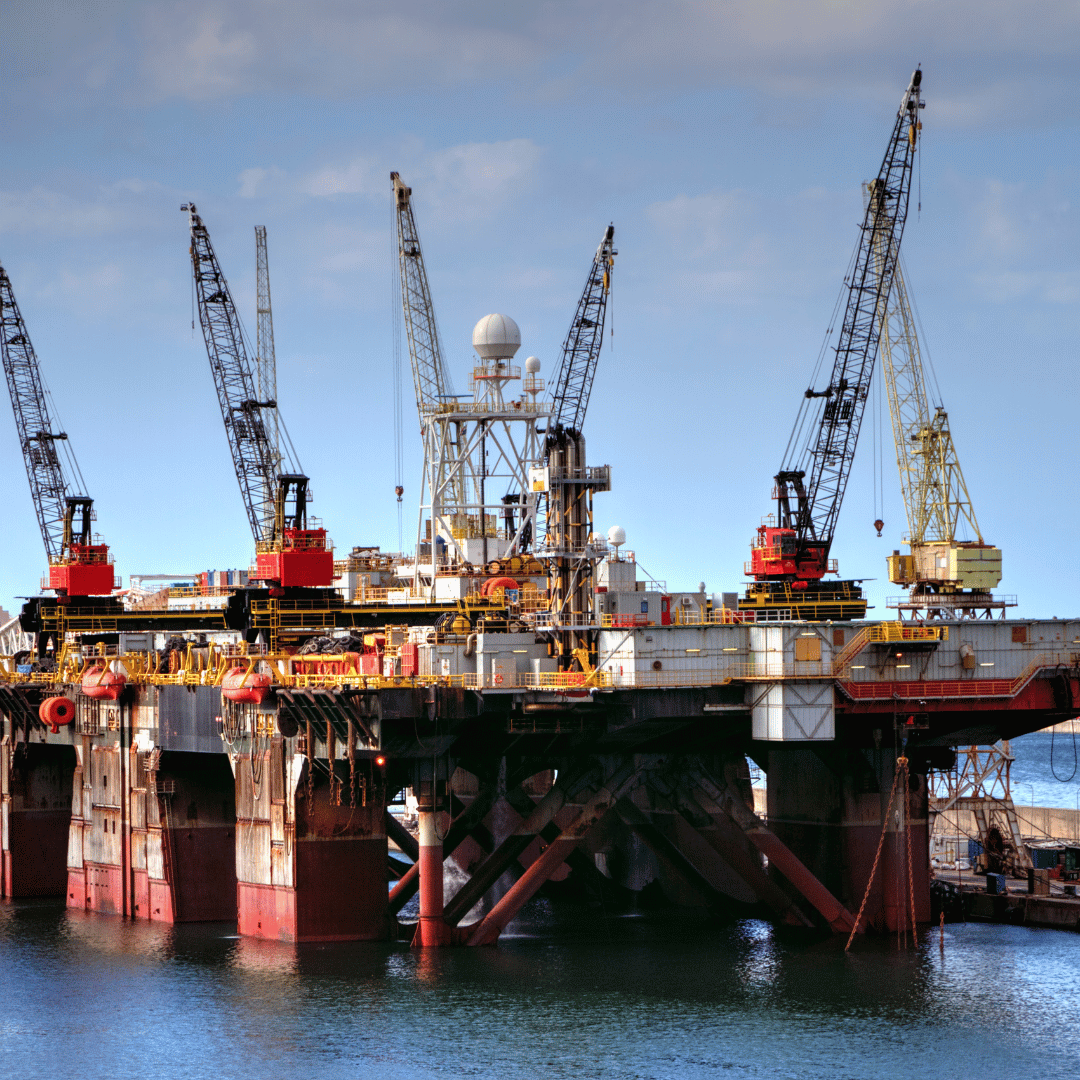

Offshore & Marine Engineering

Applied in subsea pipelines, port structures, dredging, and jetty foundations. Engineered for harsh marine environments with superior corrosion resistance.

Slurry & Ash Handling Systems

Used in power plants and mining sectors to carry slurry, ash, and abrasive materials. Offers excellent wear resistance and strength under continuous flow conditions.

IS Standards & Specification

| MS ERW Black Round | |

| IS 3589 | |

Why Choose Asian Virat GP/GC Coils & Sheets?

-

Premium-Quality Helical Welded Pipes

Narmada SAW Pipes are manufactured using precision-controlled spiral welding techniques, ensuring high strength and reliability.

-

High Load-Bearing Capacity

These pipes are designed for high-pressure and high-temperature environments, making them suitable for oil & gas and water transportation.

-

Cost-Effective & Large-Diameter Solutions

Spiral welding allows for greater pipe lengths and larger diameters at a lower production cost, making HSAW pipes ideal for large infrastructure projects.

-

Industry-Compliant & Certified

All HSAW pipes meet international standards like, ASTM, and IS 3589, ensuring top-tier quality.

-

Reliable & Fast Delivery

We prioritize timely order fulfillment, catering to bulk supply for infrastructure and industrial projects.

-

Built From Purity

At Asian Steels, every product is crafted from 100% pure steel – we never use scrap. This ensures superior strength, consistent quality, and long-term reliability in every structure built with us.

Frequently Asked Questions (FAQs)

HSAW pipes, also known as Spiral Welded Pipes, are primarily used in:

- Oil and Gas Transportation: For long-distance pipelines carrying crude oil, natural gas, and petroleum products.

- Water Supply Systems: Including municipal and industrial water distribution.

- Structural Applications: Such as piling, bridge construction, and infrastructure projects.

- Sewage and Drainage: For wastewater management and irrigation systems.

The spiral welding process allows for:

- Flexibility in Diameter Production: Enabling the manufacture of various diameters using the same width of steel strip.

- Cost-Effectiveness: Reducing production costs, making HSAW pipes a budget-friendly option for large-diameter requirements.

Enhanced Strength: The spiral seam distributes stress more evenly, improving the pipe’s ability to withstand internal and external pressures.

Narmada HSAW pipes adhere to international standards such as ASTM, and IS 3589, ensuring quality and reliability for various applications.

Yes, HSAW pipes are designed to handle high-pressure conditions, making them suitable for transporting oil, gas, and water over long distances.

Yes, we provide coatings such as guniting, food grade epoxy coating, inside mortar lining, zinc oxide amongst others.